Knowledge

Introduction to Examples of Microscopic Fracture Analysis

Fracture surface analysis holds a particularly important position in fracture failure analysis, as various information related to fracture is recorded on the fracture surface. Through the analysis of the fracture surface, the cause of fracture and its influencing factors can be identified. Microscopic fracture surface analysis mainly utilizes instruments such as metallographic microscopes, scanning electron microscopes (SEM), transmission electron microscopes (TEM), and electron probe microanalyzers (EPMA) to study the microscopic process of fracture, the fracture mechanism, and analyze various influencing factors leading to failure.

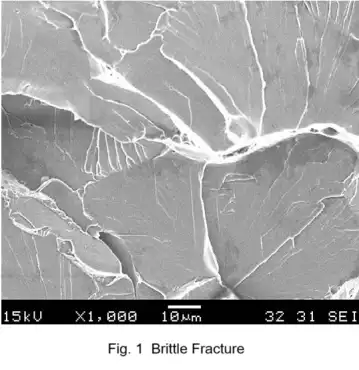

I. Brittle Fracture Surface

Introduction: (1) The typical fracture surface of brittle fracture is cleavage fracture. (2) The fracture surface is composed of small planes with steps of the size of crystal grains (see Figure 1 below). The cleavage plane is the cracked crystal plane, and the steps are called cleavage steps, which are formed when the cleavage crack propagates and intersects with screw dislocations, transferring from one cleavage plane to another. Steps can also be formed through secondary cleavage or tearing.

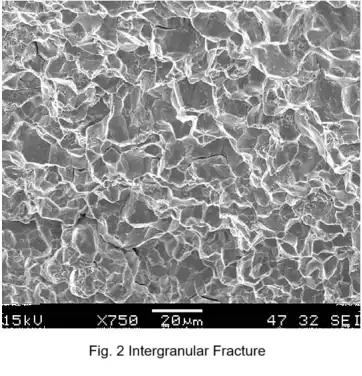

II. Intergranular Fracture

Introduction:

(1) It is the separation of grains in a polycrystalline material along the grain boundaries. The most fundamental microscopic feature is the sugar-like morphology with grain boundary facets (i.e., small planes) (see Figure 2 below).

(2) Hydrogen embrittlement, stress corrosion, creep, temper embrittlement, and welding hot cracking are often intergranular fractures.

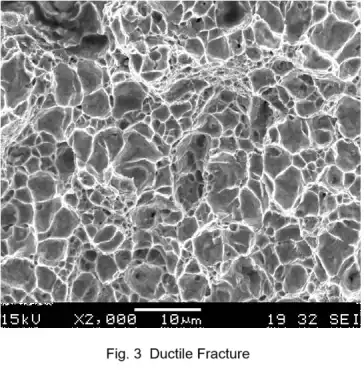

III. Ductile Fracture

Introduction:

(1) The microscopic feature of the fracture surface is the presence of a large number of dimples (as shown in Figure 3 below). This is because during the plastic deformation of the material, cracks first appear around second-phase particles such as inclusions and precipitates or in areas with defects, forming microvoids. As further plastic deformation occurs, these microvoids grow, coalesce, and eventually lead to fracture.

(2) Macroscopically, ductile fracture will definitely have a dimple-type electron metallographic structure. However, macroscopic brittle fracture may also show dimples microscopically. For instance, when a specimen meets the plane strain condition and undergoes rapid unstable low-energy propagation, the entire specimen fails in a brittle manner. But in the microscopic regions on both sides of the fracture surface, shear deformation may still occur, resulting in a microvoid-type low-energy tear (assuming no cleavage occurs at this time), and the electron metallographic structure is dimple-type.

Ⅳ. Fatigue Fracture Surface

Introduction:

(1) Fatigue striations on the fracture surface may be continuously distributed, as seen in aluminum alloys, titanium alloys, and austenitic steels; or they may be discontinuously distributed, as observed in structural steels and high-strength steels (see Figure 4 below).

(2) The spacing of fatigue striations gradually widens as the crack propagation length increases and also widens with the increase of cyclic stress.

(3) Each stress cycle forms a fatigue crack, meaning there is a corresponding relationship between the fatigue striation spacing and the crack propagation rate.

(4) There are plastic fatigue striations and brittle fatigue striations. Brittle fatigue is rare and has only been observed in a few materials such as high-strength aluminum alloys. Its characteristic is that the fracture path is in a radial fan shape, and the fatigue striations are divided into short and flat segments by radial steps.

Vigor specializes in producing high-quality castings and Forgings. If you have any questions, demands, need new parts to be developed orto improve your supply chain, please feel free to contact us info@castings-forging.com