Knowledge

How does surface treatment work

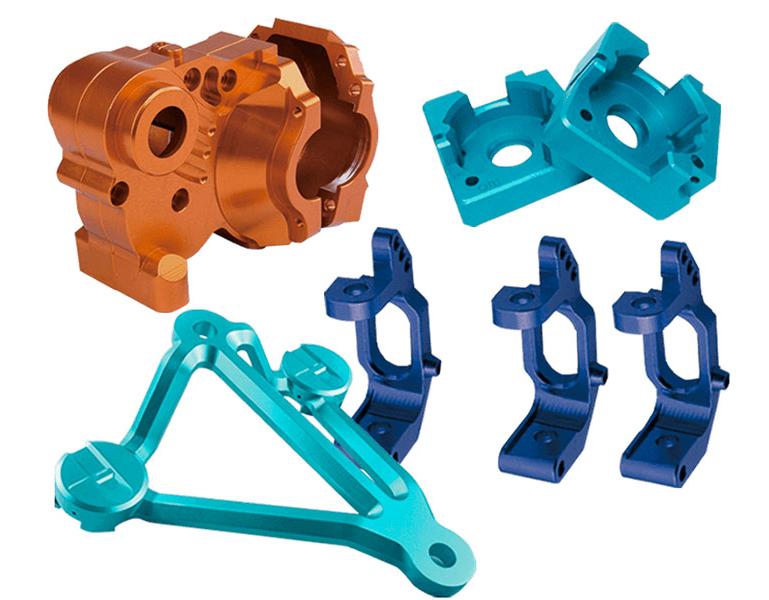

No matter how good the quality of the finished parts is, the quality of the metal surface treatment can further improve its performance.

In the manufacturing process of metal parts, surface treatment is an indispensable link. Appropriate surface treatment can not only beautify the appearance of metal components but also significantly extend their service life.

This article will deeply analyze several common surface treatment techniques and their working principles, aiming to help readers have a more comprehensive understanding of the essence of this field. Now, let's unveil the mystery of surface treatment together!

How does surface treatment work?

Surface treatment is a process of modifying or protecting the material surface through a series of process steps to improve the material's corrosion resistance, wear resistance, electrical conductivity, aesthetics, or other specific properties.

The specific methods of surface finish vary depending on the material and the required properties, but generally follow the following basic steps:

1. Pre-cleaning: First, the material surface needs to be thoroughly cleaned to remove grease, dirt, oxides, and other impurities. This can be achieved through solvent cleaning, alkaline or acidic cleaning, electrochemical cleaning, or ultrasonic cleaning, etc.

2. Surface preparation: Depending on the surface treatment requirements, further preparation of the surface may be necessary, such as roughening to increase the adhesion strength of the coating to the substrate, or activation/passivation to change the chemical properties of the surface.

3. Coating or treatment application: Apply the required coating or specific finish to the clean and prepared surface.

This may include electroplating, thermal spraying, electrophoretic coating, painting, anodizing, chemical plating, etc. The choice of coating depends on the required performance, such as corrosion resistance, wear resistance, electrical conductivity, or aesthetics.

4. Curing and drying: After coating or treatment, curing and drying are usually required.

This can be achieved through heat treatment (such as oven curing) or natural drying to ensure that the resins, curing agents, and other components in the coating undergo chemical reactions to form a strong coating and remove moisture or solvents from the coating.

5. Inspection and quality control: Finally, inspect the treated surface to ensure it meets the predetermined performance requirements. This may include visual inspection, thickness measurement, adhesion testing, corrosion resistance testing, etc.

What are the most common surface treatment techniques?

The most common surface treatment techniques mainly include the following categories:

1. Mechanical surface treatment

|

science and technology |

description |

|

grind |

The use of grinding products to form lines or remove surface defects on the surface of the workpiece can achieve a decorative effect. |

|

polishing |

Improve the gloss and flatness of the material surface to make it smoother. |

|

sand blast |

The process of cleaning and roughening the surface of the substrate by the impact of high-speed sand flow is to form a high-speed jet with compressed air as the power, and spray the spraying material to the surface of the workpiece to be treated at high speed, so as to change the appearance or shape of the surface of the workpiece. |

2. Chemical surface treatment

|

science and technology |

description |

|

electroplate |

A layer of metal or alloy is deposited on the metal surface to improve the corrosion resistance and appearance of the product. Common types of electroplating include galvanizing, chromium plating, nickel plating, etc. |

|

anodic oxidation |

It is mainly used for the surface finishing of aluminum and its alloys to improve corrosion resistance by forming oxide film. |

|

deactivation |

Clean the stainless steel surface with acid solution to remove pollutants and promote the formation of passive film on the newly created surface. Passivation finishing mainly improves the corrosion resistance of stainless steel material by dissolving all carbon steel pollutants, sulfide inclusions and so on on the stainless steel surface. |

|

scouring |

Use an acid to remove impurities (including high temperature oxides produced by welding or heat treatment) from the surface of stainless steel materials, and etch some corroded surfaces. |

3. Coating and Finishing

· Powder Coating: Powder coating is evenly applied to the surface of the workpiece through methods such as electrostatic spraying and then cured to form a coating.

· Painting: Paint is sprayed onto the surface of the workpiece using a spray gun to form a uniform coating.

4. Heat Treatment

· Heat Treatment: Such as quenching and tempering, the internal structure of the material is altered through heating and cooling processes to enhance the material's strength, toughness, and durability.

· Laser Surface Modification: A laser beam is used to rapidly heat and cool the surface of the workpiece, thereby changing the surface structure and improving surface hardness, wear resistance, and corrosion resistance.

How does surface treatment improve product performance?

Surface treatment is a key process for enhancing product performance. The specific effects include:

1. Enhancing corrosion resistance and wear resistance: Electroplating (such as chrome plating and zinc plating) forms a protective layer, and anodic oxidation and passivation treatment form isolation films, all of which improve corrosion resistance and enhance wear resistance.

2. Improving electrical conductivity: Fine sandblasting cleans the surface to increase the contact area; electroplating gold, silver, and other metals can significantly improve the electrical conductivity of electronic components.

3. Providing decorative finishes: Spraying colored paint, electroplating metal textures, printing patterns and text, all of which enhance the aesthetic appeal and added value of the product.

Reducing friction and improving mechanical performance: Improving the material and roughness of the contact surface, using wear-resistant materials; applying lubricants to form an oil film, significantly reducing friction, widely used in the automotive and mechanical fields.

What challenges does surface treatment face?

The challenges of surface treatment include:

Technical aspects:

1. High precision requirements: The development of manufacturing has promoted the increase in precision requirements, which demands advanced machine tools, high-precision tool holders, and a stable environment.

2. Processing of new materials: High-strength alloys, ceramics, and other materials are difficult to process and prone to tool wear and surface cracks. New processing methods need to be explored.

Cost:

1. High equipment and process costs: This includes procurement, maintenance, and training, which limits the popularization among small and medium-sized enterprises.

2. Output issues: There are many influencing factors, leading to increased costs and affecting competitiveness.

Human resources:

1. Shortage of high-quality talents: They need in-depth professional knowledge, rich experience, and a rigorous attitude. The long training period restricts technological development.

Market competition and environment:

1. Intense market competition: It is necessary to ensure quality while reducing costs and improving efficiency.

2. Energy consumption and pollution: High-speed and high-precision processing consumes a large amount of energy, and it is necessary to achieve green and sustainable development.

How is surface treatment used in different industries?

Advanced surface treatment technology has had a profound impact on multiple industries by significantly improving product quality, efficiency, and durability. Specifically:

1. Automotive industry

In the pursuit of both aesthetics and functionality, the automotive industry highly relies on advanced surface treatment technology.

Whether it is the polishing of body panels or coating technology used to enhance corrosion resistance, these surface treatments play a crucial role in ensuring the vehicle's durability and visual appeal.

2. Aerospace industry

In the aerospace industry, cutting-edge surface treatment technologies, such as CNC grinding and laser texturing, are widely used in the production of high-reliability components. These components not only operate reliably in extreme environments but are also manufactured with extremely high precision and tolerances.

3. Biomedical industry

The biomedical industry also benefits from advanced surface treatment technology. By providing smooth and biocompatible surfaces for implants and medical devices, these technologies reduce the risk of infection and improve patient outcomes.

4. Consumer goods industry

In the consumer goods sector, advanced surface treatment technology not only enhances the appearance appeal of products but also significantly improves their durability.

This makes consumer products more competitive in the market and extends their lifespan, meeting consumers' pursuit of a high-quality life.

5. Electronics manufacturing

Electronics manufacturers use advanced surface treatment technology to significantly improve the durability and overall performance of electronic devices.

For example, in the manufacturing of consumer electronics such as smartphones and computers, key technologies such as grinding and coating are crucial for creating smooth and highly conductive surfaces.

What are the different surface finish standards and symbols?

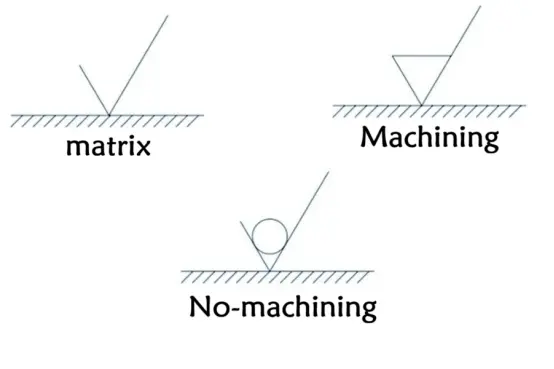

Surface finish symbols

In manufacturing and engineering, understanding surface roughness symbols and roughness parameters is crucial. These parameters are the key language for evaluating surface quality, functionality, and suitability. Common parameters include:

1. Ra: Average surface roughness is a fundamental assessment parameter, representing the arithmetic mean of the absolute values of the deviations from the mean line of the surface profile, reflecting the average condition of the surface texture.

Ra is crucial for applications such as surface contact, wear, and lubrication, and is typically measured in microinches (μin) or micrometers (μm). It is calculated by averaging the absolute values of the vertical deviations from the mean line over the length of the surface sample.

2. Rmax series: It represents the vertical distance between the highest peak and the lowest valley on a surface, reflecting the extreme irregularity of the surface.

It is crucial for applications requiring tight seals or smooth sliding surfaces. The units are usually μin or μm. It is obtained by measuring the vertical distance between the highest peak and the lowest valley along the sample length.

3. Rz: An international standard parameter, which divides the roughness profile into five segments to fully understand the surface texture, measures the height difference between the highest peak and the lowest valley in each segment (Rt) and takes the average.

This is very important for high-precision engineering applications that require a detailed understanding of surface peaks and valleys. The units are also μin or μm. To calculate, first measure the Rt of each of the five segments along the evaluation length, and then find the average Rz.

Surface finish standards

Understanding and paying attention to surface finish standards are crucial for consistency and quality assurance in the manufacturing process. These standards provide clear guidelines for the measurement and classification of surface texture.

1. ISO (International Organization for Standardization) 1302 standards:

This series of standards covers methods for specifying, measuring, and indicating surface finish. ISO standards are widely used worldwide and are applicable to various materials and finishing processes. They are crucial for ensuring global manufacturing compatibility and high quality.

2. ASTM (American Society for Testing and Materials) Y14.36M standards:

ASTM provides a set of measurement standards and surface finish characterization. These standards dominate in the US manufacturing industry and provide a solid foundation for quality control, product specification development, and manufacturing process optimization.

Summary

There are many types of surface treatment technologies, each with its own characteristics. In practical applications, the appropriate surface treatment technology should be selected based on a comprehensive consideration of factors such as material type, product performance requirements, and cost budget.

With the advancement of science and technology and the development of industry, surface treatment technologies are constantly innovating and upgrading. In the future, more environmentally friendly, efficient, and intelligent surface treatment technologies will become the development trend.

By deeply understanding the working principles and application scenarios of these technologies, we can better grasp the development trends and opportunities of modern industrial manufacturing. Q&A

1. What is surface treatment process?

Surface treatment process is a series of procedures that change the surface characteristics of materials through physical, chemical or mechanical methods. These processes aim to improve the appearance of materials, enhance corrosion resistance, increase hardness, change the coefficient of friction or meet other specific performance requirements. Common surface treatment processes include spraying, electroplating, anodizing, thermal spraying, laser processing, etc.

2. How to achieve surface finish?

Surface finish is usually achieved through mechanical processing, polishing, grinding or chemical etching. Mechanical processing such as milling and turning can initially form a smoother surface; polishing involves rubbing the surface of the material with a polishing agent to remove minor scratches and unevenness; grinding uses grinding tools and abrasives to make the surface finer; chemical etching removes part of the material surface through chemical reactions to achieve a smooth effect.

3. What is the completed process like?

The surface treatment process usually includes three stages: pretreatment, surface treatment and post-treatment. The pretreatment stage mainly involves cleaning and preparing the material surface to remove oil, dust, oxide layers and other impurities; the surface treatment stage involves selecting the appropriate process based on specific needs to treat the material surface; the post-treatment stage involves necessary curing, drying, inspection or further processing of the treated surface to ensure that the performance and appearance of the coating or electroplating meet the requirements.

4. Why use surface treatment?

There are many reasons for using surface treatment, mainly including the following aspects:

First, to improve the appearance of materials and increase the aesthetic appeal and market value of products;

Second, to enhance the corrosion resistance of materials and extend their service life;

Third, to increase the hardness, wear resistance and scratch resistance of materials;

Fourth, to change the coefficient of friction to adapt to specific application scenarios; Fifth, to meet specific performance requirements such as electrical conductivity, thermal conductivity, lubricity or anti-reflection.

In addition, surface treatment can also be used for identification, anti-counterfeiting or other specific functions.