Knowledge

Heat Treatment Process of 17-4PH Stainless Steel (Part Two)

The heat treatment strengthening mechanism of 17- 4PH stainless steel

During the solution treatment of 17-4PH martensitic stainless steel, elements such as copper and niobium dissolve into the austenite grains. After cooling, supersaturated copper and niobium martensite is obtained, achieving the first strengthening. Then, during the aging process, the supersaturated copper and niobium elements in the grains precipitate, which provides the second strengthening for the matrix. This is the main strengthening method for 17-4PH steel.

Different heat treatment processes can result in different microstructures and properties, but the strengthening mechanism is the same, which is related to the precipitation of phases. The distribution of ε-Cu, NbC, M23C6 and other precipitated phases varies, and so does the material's performance. The yield strength of precipitation-hardened alloys is determined by the interaction of the precipitated phases with dislocations. When the precipitated phase particles are extremely fine and dispersed, and distributed densely, dislocation lines will be blocked and unable to pass through these particles, thereby increasing the alloy's yield strength and eventually leading to alloy embrittlement. When the precipitated phase particles are relatively large and distributed sparsely, dislocations can bypass these precipitated phase particles according to the Orowan mechanism, and dislocation lines will no longer be blocked, resulting in a decrease in the alloy's yield strength. Therefore, when there is a large amount of reverse transformation austenite in the aged 17-4PH steel, due to the larger ε-Cu particles in the reverse transformation austenite compared to those in the martensite and their sparser distribution, they have little or no hindrance to dislocations, thus reducing the alloy's yield strength. Generally speaking, after quenching, 17-4PH steel has a small amount of retained austenite. These retained austenite particles are very small and become the core of reverse transformation austenite during tempering. Therefore, the more retained austenite in the alloy, the more reverse transformation austenite will be generated during aging. Therefore, when the content of elements promoting the formation of martensite (such as C) in the alloy is low, and the content of austenite stabilizing elements (such as N) is too high, there will be more retained austenite after quenching, and more reverse transformation austenite after tempering, thereby reducing the alloy's yield strength. At the same time, as the aging temperature increases, reverse transformation austenite begins to form and grow, resulting in an increase in the amount of retained austenite at room temperature and a decrease in strength. Therefore, for materials with strength requirements, the heat treatment process should be reasonably formulated and the amount of reverse transformation austenite in the microstructure should be strictly controlled. ε-Cu is the main strengthening phase in 17-4PH steel. In recent years, there has been an increasing amount of research on its morphology. In the past, it was generally believed that "ε-Cu is spherical in all cases". However, research has found that the ε-Cu phase precipitated from the martensite matrix is smooth and short rod-shaped, while the ε-Cu phase precipitated from austenite (reverse transformation austenite) is spherical. This is because both austenite and the ε-Cu phase have a face-centered cubic lattice, and the interface energy between them is very small, so the precipitated ε-Cu phase is spherical. Martensite has a body-centered cubic lattice, and the lattice difference with the face-centered cubic ε-Cu phase is large, so the interface energy between them is high, and the precipitated ε-Cu phase is rod-shaped. Zhang Hongbin et al. also studied the morphology of the ε-Cu phase in 17-4PH steel. They found that the ε-Cu phase precipitated from the martensite matrix is nearly spherical, finely dispersed and randomly distributed, and has a strong interaction with dislocations. As the aging temperature increases, the particle size increases and the interaction with dislocations weakens. However, the ε-Cu phase precipitated from the reverse transformation austenite is relatively large, smooth and short rod-shaped, oriented perpendicularly to each other, and ε-Cu with the same orientation has a tendency to linearly arrange at certain intervals. When its particle size is small, it has a weak interaction with dislocations. As the aging temperature increases, its particle size increases and it has no interaction with dislocations at all. Zhang Hongbin et al. studied the strengthening mechanism from the perspective of the morphology of ε-Cu and ultimately concluded that the excessive amount of reverse transformation austenite or retained austenite in 17-4PH steel is the fundamental reason for the decrease in the yield strength of this steel.

Conclusion

Precipitation-hardening stainless steel has the advantages of high strength and good corrosion resistance. Its corrosion resistance is not only related to the chemical composition but also to the heat treatment, and heat treatment is the key to adjusting its performance. The solution temperature is generally selected at 1040 ℃. Both too high and too low temperatures will affect its performance. Aging treatment can improve its comprehensive mechanical properties. On the basis of the traditional process, adding adjustment treatment can refine the martensite matrix structure and improve the corrosion resistance of the material.

Both domestic and foreign researchers have conducted some studies on the strengthening mechanism of 17-4PH stainless steel and achieved some results. It is generally believed that it is related to the precipitation of ε-Cu, and the strength of the material is determined by the state of the interaction between the strengthening relative dislocation lines. However, the analysis of the morphology of ε-Cu is not the same. Generally speaking, the research on the heat treatment process of 17-4PH steel is already quite mature. In actual production, the heat treatment process can be selected according to the specific working conditions to achieve the required performance.

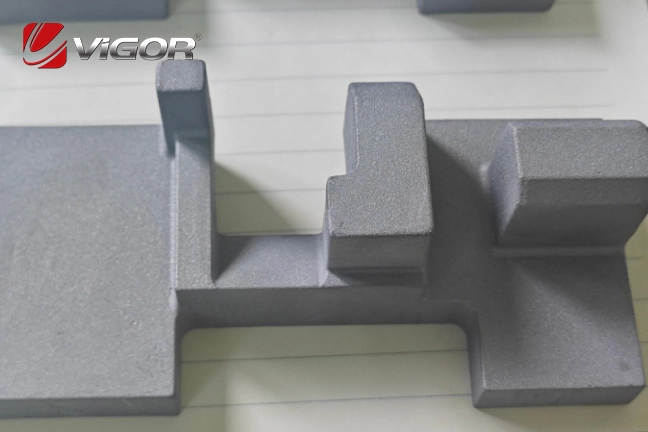

Vigor has rich experience in producing 17-4PH and the post treatment. If you have any question, demand, new parts need to be developed or improve your supply chain, please feel free to contact us info@castings-forging.com