Knowledge

Gear Plates Surface Strengthening by Shot Blasting

As a key component in mechanical transmission systems, the lifespan of gears directly affects the performance and reliability of the entire mechanical equipment. Shot peening, as a common surface strengthening process, can effectively improve the surface properties of gears. This paper deeply explores the influence mechanism of shot peening on the lifespan of gears, analyzes the correlations between shot peening process parameters, gear materials, working conditions, and gear lifespan, and provides a theoretical basis and practical guidance for the shot peening strengthening treatment and lifespan improvement of gears.

Gears play a crucial role in mechanical transmission by transmitting power and motion. During operation, they are subjected to complex alternating loads, which can lead to problems such as fatigue failure and wear, thereby affecting their lifespan. Shot peening is a process that uses a high-speed stream of shot to impact the gear surface, causing plastic deformation and forming a residual compressive stress layer, while also refining the surface grains. This enhances the surface strength, hardness, and fatigue resistance of gears. Studying the impact of shot peening on gear lifespan is of great significance for optimizing gear manufacturing processes and improving the reliability of mechanical equipment.

II. Improvement of Gear Surface Properties by Shot Peening

2.1 Introduction of Residual Compressive Stress

When a high-speed projectile impacts the surface of a gear, the surface material undergoes plastic deformation, generating residual compressive stress within the deformed layer that is opposite in direction to the working stress. This residual compressive stress can counteract part of the tensile stress generated during the gear's operation, reduce the degree of stress concentration, and thereby effectively suppress the initiation and propagation of fatigue cracks, significantly enhancing the gear's fatigue life. For instance, in automotive transmission gears, after shot peening treatment, the residual compressive stress on the gear surface can reach several hundred megapascals, increasing the gear's fatigue limit by 20% to 30%.

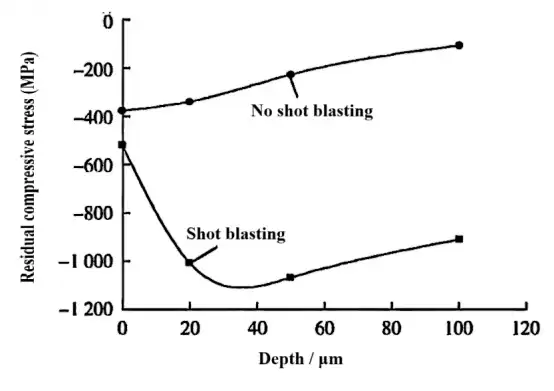

The residual compressive stress on the gear surface can resist the tensile stress caused by meshing during high-speed operation, significantly improving the gear's fatigue resistance. Figure 2 shows the trends of residual compressive stress on the gear surface and at different ranges of the gear root before and after shot peening.

Figure 2: Residual compressive stress of gears before and after shot peening

As shown in Figure 2, the residual compressive stress at the tooth root of the gear after shot peening is significantly increased compared to that without shot peening. The surface residual compressive stress of the gear sample increases from -378 MPa to -521 MPa after shot peening, an increase of 37.8%. The maximum residual compressive stress in the subsurface reaches -1069 MPa. This indicates that shot peening can generate a considerable residual compressive stress on the gear surface, and the residual compressive stress shows a trend of first increasing and then decreasing with the increase of layer depth.

2.2 Enhancement of Surface Hardness

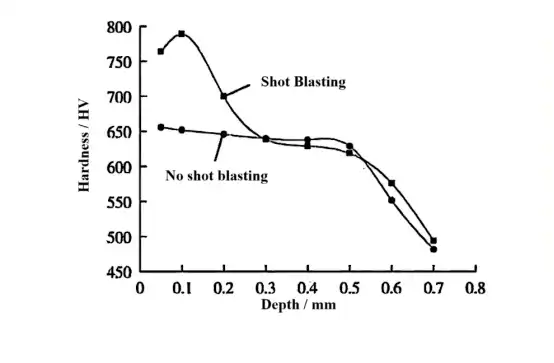

Shot peening impacts refine the surface grains of gears, increase the grain boundaries, and hinder the movement of dislocations, thereby enhancing the surface hardness. Meanwhile, the repeated collisions between shot peening balls and the surface during the shot peening process also cause work hardening of the surface material. The increase in surface hardness strengthens the wear resistance of the gear surface, reduces wear during operation, and extends the service life of the gears. In some heavily loaded gears, shot peening can increase surface hardness by 10% - 15% and reduce wear by 30% - 40%.

Figure 3: Hardness distribution of gear root surface and at different depths before and after shot peening.

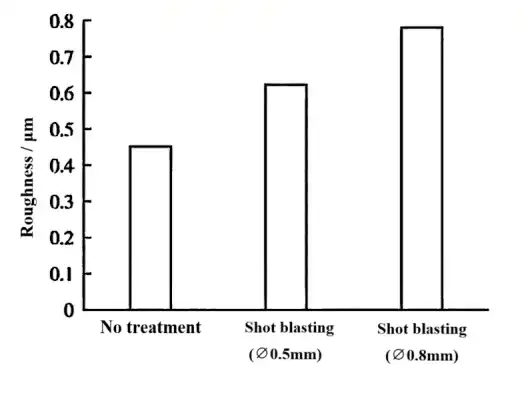

2.3 Improvement of Surface Roughness

Reasonable shot peening process parameters can improve the surface roughness of gears. Although the shot peening process itself will cause tiny pits on the surface, by controlling parameters such as the size of the shot, the shot velocity and the shot time, the surface can be made smoother and the surface roughness reduced. A lower surface roughness can reduce friction and noise during gear meshing, decrease stress concentration, and enhance the transmission efficiency and service life of gears.

Figure 4: Surface roughness of gears before and after shot blasting

III. Factors Affecting the Service Life of Gears after Shot Peening

3.1 Shot Peening Process Parameters

3.1.1 Shot Size

The size of the shot directly affects the impact energy and coverage area of the shot peening on the gear surface. Larger shots have higher impact energy, which can produce a deeper plastic deformation layer and higher residual compressive stress, but may increase surface roughness; smaller shots have relatively lower impact energy, but can achieve a finer surface and improve surface quality. When choosing the shot size, a comprehensive consideration should be given to the material, size and working requirements of the gear.

3.1.2 Jet Velocity

The higher the jet velocity, the greater the kinetic energy of the projectiles, the stronger the impact on the gear surface, and the more obvious the residual compressive stress and surface hardening effect produced. However, an excessively high jet velocity may cause defects such as cracks on the gear surface, thereby reducing the gear's lifespan. Therefore, it is necessary to determine an appropriate range of jet velocities to ensure the strengthening effect while avoiding damage to the gear surface.

3.1.3 Jetting Time

The jetting time determines the number of impacts and coverage of the shot peening on the gear surface. If the jetting time is too short, the expected strengthening effect cannot be achieved; if it is too long, it may cause excessive hardening of the gear surface, leading to brittleness and reduced fatigue performance. Through experiments and optimization, the optimal jetting time can be determined to achieve the desired strengthening effect on the gear surface.

3.2 Gear Materials

Gears made of different materials respond differently to shot peening. Generally speaking, high-strength steel, alloy steel and other materials show more significant improvement in surface performance and a greater increase in service life after shot peening. However, for materials with higher brittleness, more caution is needed during shot peening, and process parameters should be well controlled to avoid defects such as cracks. In addition, the chemical composition and microstructure of the material also affect the distribution of residual compressive stress, surface hardening degree and fatigue performance after shot peening.

3.3 Working Conditions

3.3.1 Load Magnitude

The magnitude of the load that a gear bears directly affects its fatigue life. Under the same shot peening treatment, the greater the load, the higher the internal stress level of the gear, the faster the fatigue crack initiation and propagation, and the shorter the gear life. Although shot peening can increase the fatigue limit of gears, its life improvement effect may be limited under excessive loads.

3.3.2 Rotational Speed

The rotational speed of gears affects their surface friction with the surrounding medium and heat exchange conditions. At high rotational speeds, the heat generated by surface friction intensifies, which may cause changes in surface properties, such as relaxation of residual compressive stress and reduction in hardness, thereby affecting the gear's lifespan. Additionally, high rotational speeds subject gears to greater centrifugal forces, increasing stress levels and adversely impacting their fatigue performance.

3.3.3 Working Environment

Factors such as temperature, humidity, and corrosive media in the working environment can also affect the lifespan of gears. In high-temperature conditions, the strength and hardness of gear materials will decrease, and residual compressive stress may relax. In humid and corrosive environments, the surface corrosion and wear of gears will accelerate, reducing their lifespan. Shot peening can improve the corrosion resistance of gears to a certain extent, but in harsh working conditions, additional protective measures are still necessary.

IV. Shot Peening Process Optimization and Gear Life Enhancement Strategies

4.1 Process Parameter Optimization

Through extensive experiments and numerical simulations, a mathematical model was established to relate shot peening process parameters to the surface properties and fatigue life of gears. Optimization algorithms were then used to determine the optimal combination of shot peening process parameters. For instance, the orthogonal experimental design method was employed to optimize parameters such as shot size, shot velocity, and shot time, in order to achieve the maximum residual compressive stress and surface hardness while ensuring the surface quality of gears, thereby enhancing their service life.

4.2 Compound Surface Strengthening Process

Combining shot peening with other surface strengthening processes to form a compound surface strengthening process can further enhance the lifespan of gears. For instance, the combination of shot peening with chemical heat treatment processes such as carburizing and nitriding not only creates a residual compressive stress layer on the gear surface but also increases the surface hardness and wear resistance; the integration of shot peening with laser shock peening can generate a deeper and more uniform residual compressive stress layer, significantly improving the fatigue performance of gears.

4.3 Gear Design and Manufacturing Improvements

During the gear design stage, fully consider the impact of shot peening treatment on gear life, optimize the shape, size and structure of gears to reduce stress concentration. In the manufacturing process, strictly control the processing accuracy and surface quality of gears to provide a good foundation for shot peening treatment. At the same time, strengthen the quality inspection of the gear manufacturing process to ensure that the quality of gears after shot peening treatment meets the requirements.

V. Conclusion

Shot peening, as an effective surface strengthening process, plays a significant role in enhancing the service life of gears. By introducing residual compressive stress on the gear surface, increasing surface hardness and improving surface roughness, shot peening can significantly improve the fatigue resistance and wear resistance of gears, thereby extending their service life. However, the service life of gears after shot peening is influenced by various factors such as shot peening process parameters, gear materials and working conditions. To further increase the service life of gears, it is necessary to optimize shot peening process parameters, adopt composite surface strengthening processes, and improve gear design and manufacturing processes. In the future, with the continuous in-depth research on shot peening technology and the development of new materials and new processes, the application of shot peening in the gear manufacturing field will become more extensive and profound, making greater contributions to improving the reliability and service life of mechanical equipment.

China Vigor has more than 20 years experience and the strong technical team and production capabilities in die-forged gears. If you have any question, demand, related parts development or improve your supply chain, please feel free to contact us info@castings-forging.com