Knowledge

Five Major Heat Treatment Processes of Castings and Die-Forgings

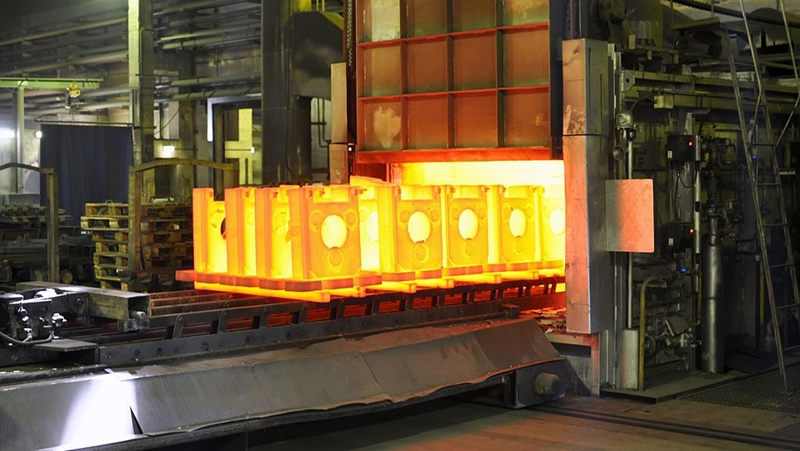

Heat treatment is a crucial process that alters the internal structure of metal materials through heating, holding at a certain temperature, and cooling to achieve the desired properties.

I. Annealing

Annealing is a heat treatment process where the workpiece is heated to a specified temperature (determined by the process), held for a certain period, and then cooled slowly (usually by furnace cooling).

1. Main purposes

Reduce hardness and soften steel to facilitate subsequent machining or cold deformation processing (such as cold drawing and cold stamping).

Eliminate internal stresses, reduce internal stresses caused by casting, forging, welding, and machining, stabilize dimensions, and reduce dimensional deformation.

Refine grains and homogenize the structure, improve and refine the coarse and uneven structure of castings or forgings, and enhance the mechanical properties of the material.

Annealing can also be a preparatory step for subsequent heat treatment.

2. Process characteristics

The key process of annealing is slow cooling. This slow cooling process allows the internal structure of the steel to have sufficient time to transform into a more stable and softer state (such as pearlite).

3. Applications

Annealing is a preparatory treatment for castings and forgings before processing, which can improve the machinability of high-carbon steel and eliminate work hardening in cold-rolled steel plates.

II. Normalizing

Normalizing is a heat treatment process where the workpiece is heated to a temperature above the austenitizing temperature (Ac₃ or Accm by 30-50°C), held for a certain period, and then cooled in air.

1. Main purposes

Normalizing generally has a better effect on grain refinement than annealing, resulting in finer and more uniform pearlite-like structures.

Eliminate overheated structures and banded structures, and prepare the structure for subsequent heat treatment.

Adjust the hardness of the material. Normalizing of low-carbon steel results in higher hardness than annealing, which is more favorable for machining.

Normalizing can also be used as the final heat treatment. For ordinary structural parts with low performance requirements, normalizing can be used as the final heat treatment to achieve certain comprehensive mechanical properties.

2. Process characteristics

The cooling rate of normalizing is faster than annealing (usually air cooling) but slower than quenching. Therefore, the material properties of normalizing are between annealing and quenching, with a shorter production cycle and higher efficiency.

3. Application examples

Commonly used in the preparatory heat treatment of carbon steel and low-alloy structural steel, to improve the structure of forgings, and as an alternative to annealing of medium-carbon steel.

III. Quenching

Quenching is a heat treatment process where the workpiece is heated to the austenitizing temperature, held for a certain period, and then rapidly cooled in water, oil, or other cooling media.

1. Main purposes

Achieve high hardness and high wear resistance. Through rapid cooling, unstable austenite is undercooled to a low temperature and transformed into a very hard and brittle unstable structure - martensite.

2. Process characteristics

The key to quenching is rapid cooling. Cooling is the core of the quenching process, and the selection of an appropriate cooling medium (water, oil, polymer solution, etc.) is very important. It is necessary to ensure a sufficient cooling rate to obtain martensite while minimizing the tendency of the workpiece to deform and crack.

3. Application examples

Various tools (such as knives, measuring tools, molds), bearings, carburized parts, and other parts requiring high hardness and wear resistance.

IV. Tempering

After quenching, the martensite structure obtained is hard but very brittle, and there are huge internal stresses within the material, making it prone to cracking and deformation and not suitable for direct use. Therefore, tempering is an indispensable process immediately following quenching.

Tempering is a process where the quenched workpiece is reheated to a temperature below the phase transformation point (A₁), held for a certain period, and then cooled.

1. Main purposes

Eliminate internal stresses, significantly reduce the brittleness and internal stresses caused by quenching, and prevent deformation and cracking of the workpiece.

Adjust mechanical properties, by controlling the tempering temperature, stabilize the structure, and achieve the desired hardness, strength, plasticity, and toughness of the workpiece. Tempering can stabilize dimensions, make the microstructure more stable, and ensure that the workpiece does not undergo dimensional changes during use.

2. Process Characteristics

The tempering temperature determines the final properties of the material. Depending on the temperature, it can be classified into the following three types:

1) Low-temperature tempering (150~250℃)

It maintains high hardness while reducing the brittleness and stress of the material. It is mainly used for tools, measuring tools, rolling bearings, etc.

2) Medium-temperature tempering (350~500℃)

It can achieve high elastic limit and yield strength, and has certain toughness. It is mainly used for springs, hot forging dies, etc.

3) High-temperature tempering (500~650℃)

It can obtain a good combination of strength, plasticity and toughness.

V. Normalizing and Tempering

Normalizing and tempering treatment is not an independent process, but a comprehensive heat treatment process combining quenching and high-temperature tempering.

1. Main Purpose

It can achieve excellent comprehensive mechanical properties, that is, high strength, good plasticity and toughness. The microstructure obtained is tempered sorbite, which is uniform and has much better comprehensive performance than that obtained by normalizing.

2. Process Characteristics

Normalizing and tempering combines the dual advantages of quenching for high strength and high-temperature tempering for high toughness.

3. Application Examples

It is widely used in various important structural parts, especially in connecting rods, bolts, gears and shafts that work under alternating loads. Because these parts not only require high strength but also sufficient toughness to withstand impact loads.

Annealing, normalizing, quenching, tempering and normalizing and tempering are five basic heat treatment processes that are interrelated and together form a complete heat treatment process system for steel.

Annealing and normalizing are generally pre-heat treatments, mainly to eliminate defects and prepare the microstructure and properties for subsequent processing or final heat treatment.

Quenching is a key step to obtain high hardness, but it must be combined with tempering.

Tempering is the subsequent process of quenching and determines the final performance state of the workpiece, which is the core link of the final heat treatment.

Normalizing and tempering is a combination of quenching and high-temperature tempering, and is a classic process for obtaining excellent comprehensive mechanical properties.

Vigor has more than 20 years experience and the professional team in Casting and Die-forging process. If you have any question or products need to do, please feel free to contact us at info@castings-forging.com