Knowledge

Dimensional changes and accurate control in investment casting

There are many systematic errors that affect the dimensional variation of castings, including four main dimensional change factors: mold processing tolerance, wax pattern shrinkage, shell expansion, and alloy shrinkage. The basic physical shrinkage from mold to wax pattern and the solidification shrinkage of the casting are the two main reasons for the final dimensional variation of the casting. Research shows that in steel castings, the dimensional accuracy of the final casting is mainly transferred from the dimensional accuracy of its corresponding wax pattern.

At present, the method for producing castings of qualified dimensions is to select the appropriate shrinkage of the pattern size. Therefore, it is very important to understand and control the factors that affect the final casting shrinkage. A lot of efforts have been made to obtain accurate mold shrinkage. Some foundries use a fixed mold shrinkage throughout the casting without considering the size or feature geometry of the casting. Others use specific mold shrinkages in the casting direction while ignoring the structural type of the casting and the constraints of the shell mold. Different investigations have been conducted on the shrinkage of wax patterns for free, fully constrained, and partially constrained feature dimensions. For steel castings with dimensions less than 25.4 mm, it is very troublesome to select the shrinkage. So far, numerical simulation methods have been used in industry to predict the dimensional changes that occur during solidification and cooling. Although there are some valuable guidelines for determining shrinkage for a certain wax material, metal, and post-treatment process, the dimensional transfer relationship between the wax pattern and its corresponding shell mold and casting is still unclear. To obtain more realistic and quantitative results, the main casting process steps and the casting geometry that affect dimensional shrinkage must be quantified and evaluated.

This paper aims to further understand the process and specific characteristics of dimensional shrinkage in investment casting. The dimensional shrinkage relationship between the wax pattern and its corresponding casting is also studied.

The free shrinkage behavior of wax patterns and castings

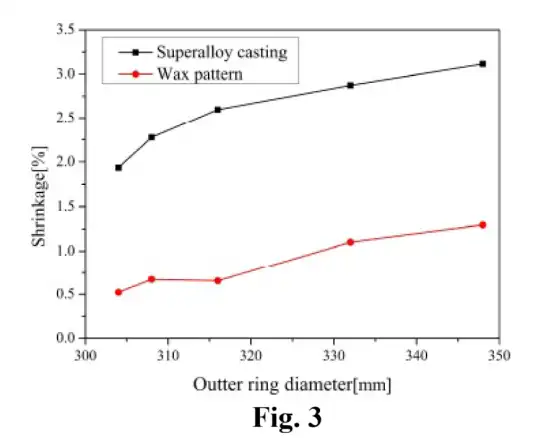

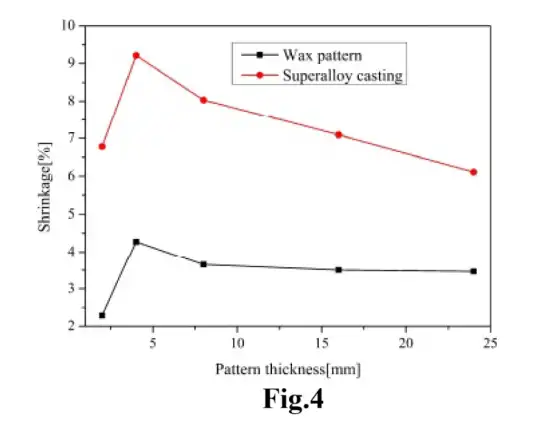

Some researchers define the outer ring diameter and thickness of wax patterns and castings as unconstrained dimensions. The shrinkage variation of the outer ring diameter of wax patterns and castings in relation to the wax pattern size is shown in Figure 3. Clearly, under free shrinkage conditions, there are typical differences in the shrinkage amounts of castings and wax patterns. The shrinkage trend of the casting size with respect to the outer ring diameter characteristic dimension is the same as that of the wax pattern. As the diameter increases, the shrinkage amounts of both the wax pattern and the casting increase simultaneously. The castings in the outer ring cool faster because they are surrounded by cold air, which leads to a greater size shrinkage of the castings during the casting process. The wax pattern solidifies instantaneously, and the total shrinkage formed throughout the casting process is relatively small. When high-temperature alloy castings are cooled from the pouring temperature of 1500°C, they shrink from liquid to solid, with significant volume changes. The solid-state shrinkage of the metal is the main influencing factor determining the final size shrinkage of the casting, as the liquid metal feeding during the solidification process has an impact. The diameter shrinkage law of the casting is derived from the corresponding wax pattern. The average shrinkage rate of the outer ring diameter is: 0.849% for the wax pattern and 2.559% for the casting. As shown in Figure 4, the shrinkage value of the outer ring thickness is much greater than that of the diameter. The shrinkage amount of a thickness of 4 mm is larger than that of other thicknesses. The reason for this is not clear, but it may be related to the influence of adjacent features. For the wax pattern, as the thickness increases from 4 mm to 24 mm, the shrinkage rate decreases from 4.28% to 3.46%. Due to the differences in cavity pressure and cooling history, the shrinkage rates of wax patterns also vary slightly. This indicates that it is difficult to determine the shrinkage rate of the wax pattern for determining the casting thickness due to the feeding from the gating and runner system. It is recommended that different wax pattern shrinkage allowance and dimensional tolerances be adopted for castings of different sizes and types.

The relationship between wax pattern and casting dimensions

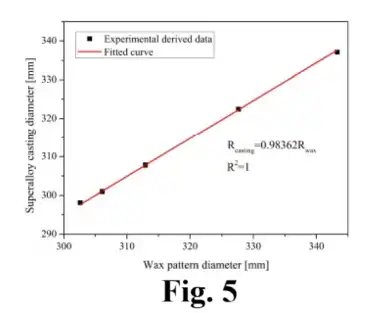

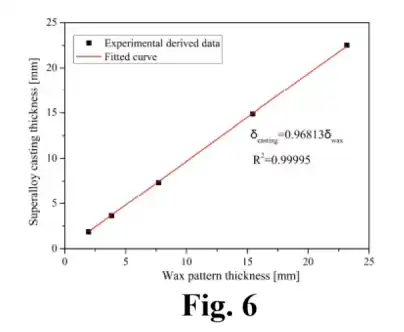

There is no definite dimensional relationship between the wax pattern and its casting. The traceability of dimensional accuracy throughout the casting process was evaluated. As shown in Figure 5, the dimensions of a single casting can be traced back to those of its wax pattern. Regarding the outer ring diameter, the wax pattern and the corresponding casting have a linear proportionality of 98.362%. For the outer ring thickness, there is also a direct linear relationship between the wax pattern and the casting, as shown in Figure 6. The thickness of the wax pattern is approximately 3.187% greater than that of the outer ring of the casting. These data indicate that to produce high-precision castings, the dimensional changes of the wax pattern must be strictly controlled.

The influence of the process on dimensional shrinkage

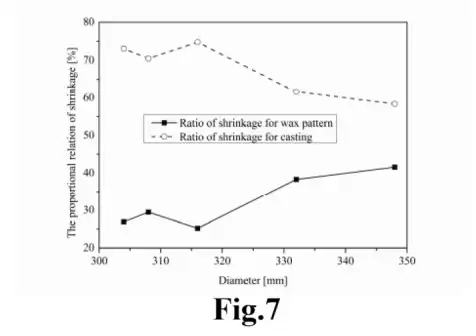

As shown in Figure 7, the influence of the wax pattern process on the final casting dimensions of the outer ring is within the range of 25.2% to 41.6%. The shrinkage ratio of the outer ring diameter caused by the wax pattern process accounts for less than 50% of the total dimensional change of the casting. Therefore, it can be concluded that among all casting processes, the dimensional accuracy of the casting is mainly affected by the dimensional changes during the thermal contraction stage. The shrinkage of the alloy is the main factor contributing to the overall dimensional change between the wax pattern mold and the corresponding superalloy casting.

Conclusion

For the unconstrained dimensions of the outer ring, the wax pattern and the casting can shrink freely. On average, the wax pattern shrinks by 0.849% and the nickel-based superalloy casting shrinks by 2.559% in the unconstrained outer ring diameter. A direct linear relationship has been established between the outer ring dimensions of the wax pattern and its casting. The linear relationship between the dimensions of the wax pattern and its casting can be used to predict the deformation of the casting. These results can be significantly applied to the design of appropriate mold allowances for ring-to-ring casting. The influence of the wax pattern process on the final casting dimensions is relatively small, ranging from 25.2% to 41.6% in the outer ring diameter. During the casting process, the wax pattern ranks second in the changes of unconstrained dimensions. It can be concluded that among all casting processes, the dimensional accuracy of the casting is mainly affected by the dimensional changes during the thermal contraction stage. The research results are of great significance for evaluating the geometry of castings and the key casting process factors that affect the shrinkage allowance of the wax pattern.

Vigor has more than 20 years experience in investment castings, if you have any question, demand, parts development or improve your supply chain, please feel free to contact us at info@castings-forging.com