Knowledge

Common Defects in Investment Castings - Surface Overburning

1. Overview

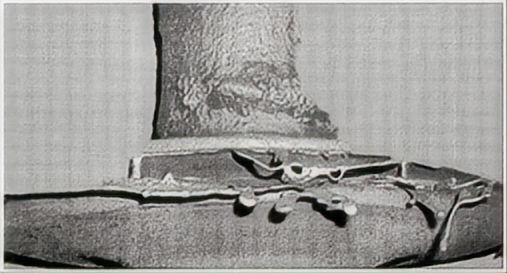

(1) Characteristics: Part of the shell has cracked. After pouring, the molten metal flows out from the cracked area of the shell under the action of dynamic and static pressure, forming irregular and excessive metal on the surface of the casting.

(2) Causes: The high-temperature strength of the shell is low, or the impact force during pouring is large, causing local cracking of the shell. The molten metal flows out from the crack, resulting in external fire running.

(3) Location: At the weakest point of the shell where it cracks.

(4) Illustration: See Figure 1.

2. Causes

(1) Low high-temperature strength of the shell. The high-temperature strength of the shell refers to its strength during the shell baking and pouring processes.

① Improper shell baking process, loss of control during operation, or the baking furnace not meeting the process requirements. Improper selection of the shell baking process, excessively high baking temperature, too rapid temperature increase, improper baking operation, or the baking furnace not meeting the process requirements all lead to delamination, cracks, and fissures on the surface layer of the mold cavity.

② Improper pouring operation. Pouring too fast results in a quadratic increase in the dynamic pressure on the inner cavity of the shell.

(2) The room temperature strength of the shell mold is low. The room temperature strength of the shell mold refers to its strength during the shell-making and dewaxing processes.

① The quality of the powder and molding sand is substandard. The powder and molding sand contain a high amount of impurities, or have a high moisture content and dust content, which causes cracks and fissures on the inner surface layer of the shell mold.

② The powder and molding sand are improperly selected. The particle size of the powder and molding sand used in each layer of the shell mold differs greatly. Due to the different shrinkage rates of each layer, the weak points of the first and second layers of the shell mold develop delamination, cracks and fissures.

③ The shell-making process parameters are inappropriate or not properly controlled. The room temperature strength of the silica sol shell mold mainly depends on the drying degree of the binder. When the drying process parameters (humidity, temperature, air speed, drying time) are improperly selected or out of control, the strength will decrease. The room temperature strength of the sodium silicate shell mold mainly depends on the hardening degree of the sodium silicate. When the hardening process parameters (concentration, temperature, hardening time) are improperly selected or out of control, the strength will decrease.

④ The dewaxing process or operation of the shell mold is improper, causing or increasing cracks. When steam dewaxing is used for resin-based mold materials (also known as "medium-temperature wax"), the steam pressure is low, the heating rate is slow, and the dewaxing time is long. When hot water dewaxing is used for wax-based mold materials (also known as "low-temperature wax"), the water temperature in the dewaxing tank is low, the dewaxing time is long, or the wax drainage from the shell mold is not smooth during dewaxing.

(3) Local damage of the shell mold. During the production process such as baking and handling, the shell mold is locally damaged due to external force.

(4) The shell has poor resistance to sudden cooling and heating. When subjected to sudden cooling or heating, the shell is prone to cracking due to its poor resistance to such temperature changes.

(5) Improper design of the gating system. During pouring, the molten metal directly impacts the cavity.

3. Prevention and Control Measures

(1) Enhance the high-temperature strength of the shell.

① Increasing the room temperature strength of the shell can effectively enhance its high-temperature strength. Additionally, the following process methods can be adopted, such as:

a. Blowing treatment. After each layer of sand is spread, use compressed air to blow away the loosely adhered and excess sand; this treatment is suitable for removing thick sand layers or loose sand accumulated in small holes, grooves, inner corners, and text areas.

b. Use quick-drying silica sol. Quick-drying silica sol shells have higher room temperature strength, higher high-temperature strength, and lower residual strength.

c. Add polymers. Adding polymers or fibers to enhance the silica sol to prepare the coating helps prevent the coating layer from cracking and can adapt to a faster drying speed. The environmental humidity can be reduced to 35%, and the wind speed can also be increased.

② Improve the shell baking process. Process parameters for baking shells: The shell temperature should be as high as possible. The baking temperature for silica sol shells is 950-1200°C, and the baking time is generally 0.5 hours; for sodium silicate shells, the baking temperature is 850-950°C, and the baking time is generally 0.5-2 hours. Ensure that the baking furnace meets the process requirements and follow the operating procedures.

③ Improve the pouring process. Control the shell temperature during pouring to be as high as possible and match it with the pouring temperature of the metal liquid. Control the pouring speed, using "fast then slow" for large parts and "slow then fast" for small parts.

(2) Enhance the room temperature strength of the shell.

① Strictly control the quality of the powder and molding sand. The impurity content of the powder and molding sand should meet the process requirements, and the moisture content and dust content should be ≤ 0.3% (mass fraction).

② Reasonably select the powder and molding sand for each layer of the shell. Reasonably choose the type of coating, such as quartz powder for carbon steel and zircon sand for stainless steel and high alloy steel; the particle size of the powder should be consistent, and it is best to use graded powder.

The type of sand for each layer should be consistent or similar to the powder of each layer; the particle size of the molding sand should be reasonable, such as 100/120 mesh for the surface layer sand, 30/60 mesh for the transition layer sand, and 16/30 mesh for the reinforcing layer sand.

③ Select reasonable shell-making process parameters and strictly control them. The hardening speed of the sodium silicate shell hardened by crystalline aluminum chloride is relatively slow. A mass fraction of 0.1% JFC can be added to the hardener to improve the penetration ability of the hardener; the strength of the shell is high.

④ Improve the dewaxing process. The key to dewaxing: before dewaxing, the shell needs to be stored for 12 to 24 hours; the dewaxing process should be "high temperature and fast". The dewaxing operation procedures must be strictly followed.

(3) Avoid local damage to the shell. Practice civilized production. During the dewaxing, baking and pouring processes of the shell, prevent it from being damaged by external forces. Once local damage to the shell is found, it is not allowed to be transported or poured again.

(4) Improve the thermal shock resistance of the shell. To prevent the shell from being subjected to sudden cooling and heating, hot shell casting should be adopted.

(5) Improve the design of the gating system to prevent the molten metal from directly impacting the mold cavity during pouring.

Vigor has more than 20 years experience and the professional team in castings and die-forging industry. If you have any question or any parts we can help, please contact us at info@casting-forging.com