Knowledge

Classification and Application of Gear Materials

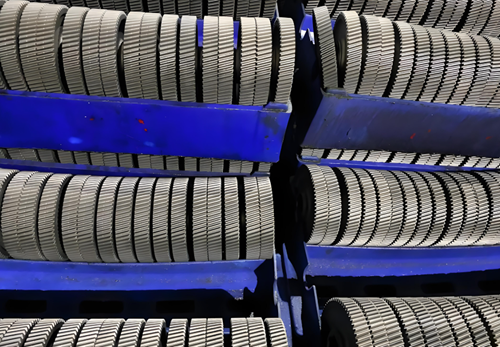

Gears, as the core components in mechanical transmission, the selection of their materials directly affects the transmission efficiency, service life, load-bearing capacity and adaptability to working environments. Different gear materials have their own advantages and disadvantages in terms of performance, heat treatment processes and application fields.

This article mainly compares and analyzes common gear materials, discussing their advantages and disadvantages, heat treatment properties and applicable scenarios, providing certain references for engineering practitioners.

Introduction to Various Gear Materials

I. Classification of Gear Materials

Gear materials are mainly classified into the following categories:

Carbon steel and alloy steel (most commonly used)

Cast iron

Powder metallurgy materials

Non-metallic materials (such as nylon, polyoxymethylene, etc.)

Surface-hardened materials (such as carburized steel, nitrided steel)

II. Comparison of Properties of Various Gear Materials

1. Carbon Steel and Alloy Steel

(1) Low-carbon Steel (20Cr, 20CrMnTi, 20CrMnMo, etc.)

Advantages:

Lower cost and easy to process. Suitable for surface hardening treatments such as carburizing and quenching to increase surface hardness (HRC 58-62) while maintaining core toughness.

Disadvantages:

Lower overall strength, not suitable for heavy-duty gears. Large deformation during heat treatment, requiring strict process control.

Heat treatment performance:

After carburizing, quenching and tempering, the surface is wear-resistant and the core has good toughness.

Typical applications:

Gears for automotive transmissions, small reducers.

(2) Medium-carbon Steel (45 steel, 40Cr, etc.)

Advantages:

Moderate strength and toughness, good overall performance after quenching and tempering.

Suitable for high-frequency quenching to achieve high surface hardness (HRC 50-55).

Disadvantages:

Poor hardenability, prone to soft spots in large-sized gears. Lower wear resistance compared to carburized steel.

Heat treatment performance:

After quenching and tempering (quenching + high-temperature tempering), the overall strength can be improved.

High-frequency quenching can increase surface hardness.

Typical applications:

Medium and low-speed gears, gears for machine tool transmissions.

(3) Alloy Steel (42CrMo, 20MnCr5, etc.)

Advantages:

High hardenability, suitable for large-sized gears.

High strength, high toughness, and good fatigue resistance.

Disadvantages:

Higher cost and slightly more difficult to process. Heat treatment performance:

Can undergo various treatments such as quenching and tempering, carburizing, and nitriding.

Typical applications:

Heavy machinery gears, wind turbine gearboxes, aircraft gears.

2. Cast iron (HT250, QT600, etc.)

Advantages:

Low cost, good casting performance, suitable for gears with complex shapes.

Good shock absorption, suitable for low-speed and high-torque applications.

Disadvantages:

Low strength, not resistant to impact, prone to brittle fracture.

Heat treatment performance:

Can be normalized or annealed to improve strength, but cannot significantly increase hardness.

Typical applications:

Agricultural machinery gears, machine tool base gears.

3. Powder Metallurgy Materials

Advantages:

Near-net shaping, reducing machining costs.

Alloy elements can be added to enhance strength.

Disadvantages:

Lower density, limited load-bearing capacity.

Poor impact resistance.

Heat treatment performance:

Density and strength can be improved through copper infiltration and heat treatment.

Typical applications:

Gears for small household appliances, gears for power tools.

4. Non-metallic materials (nylon, POM, etc.)

Advantages:

Lightweight, low noise, corrosion-resistant.

No need for lubrication, suitable for food and medical industries.

Disadvantages:

Low load-bearing capacity, not resistant to high temperatures.

Heat treatment performance:

Generally not subject to heat treatment.

Typical applications:

Printer gears, toy gears.

5. Surface-hardened materials (carburized steel, nitrided steel)

(1) Carburized steel (such as 20CrMnTi)

Advantages: High surface hardness and good core toughness.

Disadvantages: Large deformation during heat treatment.

Applications: Automotive gears, heavy-duty gears.

(2) Nitrided steel (such as 38CrMoAl)

Advantages: Small deformation, good corrosion resistance.

Disadvantages: Thin hardened layer, poor impact resistance.

Applications: Precision gears, high-speed gears.

Selection of heat treatment for various gear materials

For heavily loaded gears, alloy carburizing steels (such as 20CrMnTi and 20CrMnMo) are preferred and should undergo deep carburizing and quenching. For precision gears, nitriding steels (such as 38CrMoAl) are recommended to minimize heat treatment distortion. For low-cost gears, 45 steel after quenching and tempering or cast iron can be used. For lightly loaded and low-noise gears, powder metallurgy or engineering plastics can be selected. Summary

Different gear materials have their own characteristics in terms of strength, wear resistance, cost and adaptability to heat treatment. Reasonable selection of materials and combination with appropriate heat treatment processes can significantly increase the service life and transmission efficiency of gears. In the future, with the development of new materials (such as composite materials and 3D printed alloys), the performance of gear materials will be further optimized.

Vigor team has more than 20 years experience on section bar machining and forged gears and shafts, as well as the post treatment. If you anything we can help or you have parts need to do, please feel free to contact us at info@castings-forging.com