Knowledge

Characteristics and Evaluation of Nitriding Layer on Metal Components

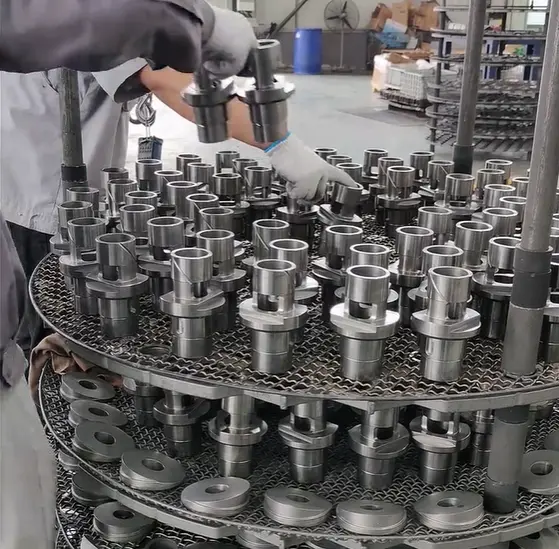

Metal components often require surface treatment to meet the requirements of working conditions. Nitriding is a process in which nitrogen is diffused into the surface of steel to form a nitrogen-rich hardened layer. It is achieved by using active nitrogen atoms produced from the decomposition of ammonia at a certain temperature (usually 500-600℃) to penetrate and diffuse into the surface layer of steel, forming iron-nitrogen alloys, thereby altering the mechanical properties of the steel surface, such as enhancing wear resistance, increasing hardness, and improving corrosion resistance. The principle is that at a certain temperature, the medium is activated to produce nitrogen atoms that penetrate the surface layer of the workpiece, thereby forming different composition structures with Fe and alloy elements in a continuous depth near the surface, changing the hardness, thermal stability, and density of the surface layer. However, since the effect of the nitriding process is not visible to the naked eye and the finished parts cannot be destroyed, quality inspections must be conducted in advance on nitriding samples under different process conditions.

Characteristics of Nitrided Layer:

Enhance surface hardness: The nitriding process can form a hard nitride layer on the metal surface, significantly improving the wear resistance and scratch resistance of components.

Improve fatigue performance: The nitride layer can reduce surface stress concentration, thereby enhancing the fatigue resistance of components and extending their service life.

Enhance corrosion resistance: The nitride layer provides an additional protective layer, reducing the contact between the metal and corrosive media, and improving the corrosion resistance of components.

Reduce deformation: As the nitriding process does not require rapid cooling or quenching, it can reduce component deformation and maintain dimensional stability.

Lower temperature: Nitriding is typically carried out at relatively low temperatures (500-600°C), which is lower than traditional heat treatment temperatures, helping to reduce energy consumption and equipment costs.

Environmentally friendly: The nitriding process uses ammonia gas, and the decomposition products, nitrogen and hydrogen, are environmentally friendly and do not produce harmful emissions.

Wide application range: Nitriding is applicable to various metal materials, including carbon steel, alloy steel, stainless steel, cast iron, etc., and is suitable for different industrial applications.

Process controllability: The nitriding process can control the depth and composition of the nitride layer by adjusting parameters such as ammonia flow rate, temperature, time, and pressure to meet different performance requirements.

Uniform surface treatment: Nitriding can form a uniform nitride layer on the entire surface of components, including complex geometries and hard-to-reach areas.

Improve anti-galling performance: The nitride layer can reduce direct metal-to-metal contact, reducing the possibility of galling and adhesion, making it suitable for applications requiring reduced friction and wear.

Improve lubrication performance: The nitride layer can enhance the lubrication performance of components, reducing friction and wear, and is suitable for components requiring long-term lubrication.

Enhance thermal resistance: Some nitride layers (such as silicon nitride) have excellent high-temperature resistance and are suitable for components operating in high-temperature environments.

Evaluation methods for nitrided layers:

1) Depth of nitridation layer

Hardness method: On the cross-section, measure the Vickers hardness from the surface and the interior until the vertical distance where the hardness is 50HV higher than the base material is reached. This distance is the depth of the nitrided layer.

Metallographic method: Cut the nitrided sample, prepare a cross-section sample, conduct metallographic etching with 4% nitric acid alcohol, and observe and measure under a metallographic microscope.

2) Nitriding hardness

The surface hardness of the nitrided samples was measured by a light-load hardness tester; the cross-sectional hardness of the nitrided samples was measured by a micro-Vickers hardness tester.

3) Penetrated layer structure

Metallographic method: The nitrided layer structure is relatively complex, with compound layers and diffusion layers (compounds of nitrogen-iron/alloy with different compositions). The morphology and distribution of nitrides significantly affect the nitriding brittleness and bonding strength. The rating can be made in reference to "GB/T 11354-2005 Steel parts - Determination of nitrided layer depth and metallographic structure inspection".

4) Residual stress

X-ray diffraction-residual stress testing: Nitriding treatment alters the composition of the near-surface structure and introduces residual compressive stress, which is quite beneficial for enhancing the fatigue strength of workpieces (shafts, gears, etc.). For parts that aim to improve wear resistance and fatigue strength, qualitative and quantitative detection of residual stress on the nitrided surface helps select more optimized process conditions.

If you have any questions or demand for product development or to improve your supply chain, please feel free to contact us at info@castings-forging.com