Knowledge

Analysis of the molten pool characteristics in laser welding

01 Preface

Laser welding technology plays a crucial role in modern manufacturing, with its core lying in the formation and rapid solidification of the molten pool. The characteristics of the molten pool not only determine the welding quality but also directly affect the microstructure and mechanical properties of metals. In recent years, with the development of laser technology and the expansion of application fields, research on the characteristics of the laser welding molten pool has become increasingly in-depth. Researchers have conducted extensive and in-depth discussions on the fluid dynamics characteristics, microstructure evolution, and pore formation mechanism of the molten pool through experimental observation, numerical simulation, and theoretical analysis from multiple perspectives.

02 Molten Pool Dynamics

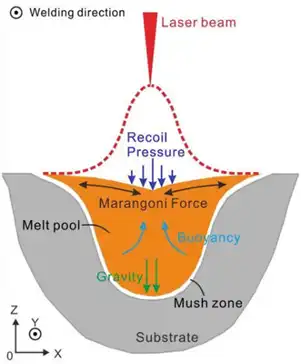

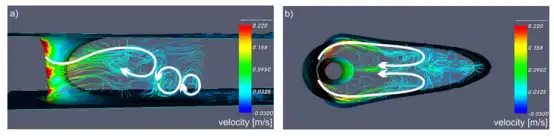

Molten pool dynamics is a key area in laser welding research, involving the formation, flow, and stability of the molten pool. Laser power and welding speed are the main parameters affecting molten pool dynamics. Higher laser power and lower welding speed usually result in a deeper molten pool, but excessive power may cause overheating of the material and formation of pores. The fluid flow in the molten pool is mainly driven by surface tension, evaporation reaction force, and buoyancy, as shown in Figure 1. These forces work together to influence the shape and stability of the molten pool.

For instance, the Marangoni convection driven by surface tension can cause a temperature gradient on the surface of the molten pool, influencing the flow pattern and cooling rate of the molten pool. The Marangoni convection forms a radial outward flow on the surface of the molten pool, transferring heat from the center to the outside and making the molten pool shallower. This flow pattern is particularly evident in high-power laser welding as it significantly alters the shape and size of the molten pool. Through numerical simulation and experimental research, these complex processes can be better understood, thereby optimizing the welding process parameters and improving the welding quality.

In addition, the evaporation recoil force is also an important factor influencing the dynamics of the molten pool. During laser welding, the evaporation of materials generates a recoil force that pushes the liquid metal in the molten pool to flow outward. This recoil force is particularly significant in high-power laser welding as it can cause significant changes in the shape and size of the molten pool. For instance, when the laser power is too high, the evaporation recoil force may cause the edges of the molten pool to bulge, affecting the quality of the welded joint.

Buoyancy is also one of the important factors influencing the dynamics of the molten pool. In the molten pool, due to the existence of temperature gradients, the hotter liquid metal rises while the cooler liquid metal descends, forming convection. This convection can improve the mixing and uniformity of the molten pool, but it also increases the instability of the molten pool. By rationally controlling the welding parameters, the buoyancy convection in the molten pool can be optimized to enhance the welding quality.

03 Microstructure and Porosity

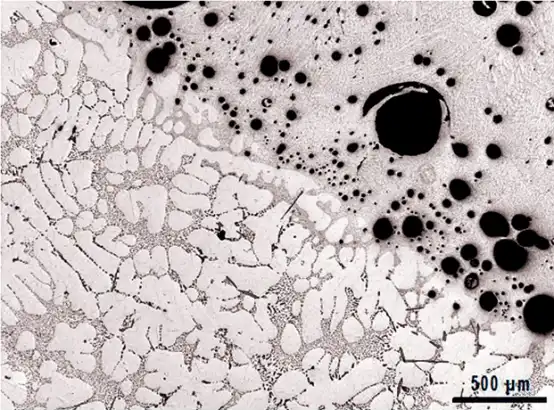

The microstructure and porosity characteristics of laser-welded joints have a significant impact on the performance of the welded joints. Rapid cooling usually leads to the formation of fine-grained structures, enhancing the hardness and strength of the welded joints. However, overly rapid cooling rates may also cause porosity, reducing the density and mechanical properties of the welded joints. The formation of porosity is mainly related to the solubility of gases in the molten pool, evaporation, and solidification processes. For instance, when welding aluminum alloys, the solubility of hydrogen in liquid aluminum alloys is much higher than in solid aluminum alloys. Therefore, during the welding process, hydrogen will precipitate from the liquid aluminum alloy, forming porosity, as shown in Figure 3. By optimizing welding parameters, such as reducing the welding speed and improving the quality of shielding gas, the formation of porosity can be effectively reduced. Additionally, using low dew point shielding gas can also reduce the hydrogen content, thereby lowering the probability of porosity formation.

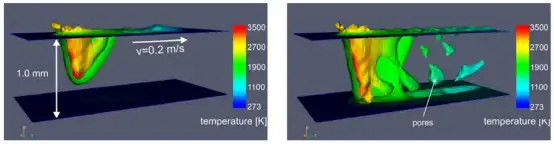

The evolution of microstructure is also closely related to the thermal cycle during the welding process. Reasonable control of the thermal cycle can achieve an ideal microstructure and improve the performance of the welded joints. For example, when welding austenitic stainless steel, rapid cooling leads to the formation of fine-grained martensitic structures, enhancing the hardness and strength of the welded joints. However, overly rapid cooling rates may also cause crack and porosity formation, reducing the toughness of the welded joints, as shown in Figure 4. By reasonably controlling welding parameters, the thermal cycle can be optimized to achieve an ideal microstructure and improve the performance of the welded joints. Moreover, the evolution of microstructure is also related to the chemical composition of the material. Different chemical compositions can lead to different phase transformation behaviors and microstructure structures. For instance, when welding low-carbon steel, adding an appropriate amount of manganese and silicon can promote the formation of ferrite, enhancing the toughness of the welded joints. By rationally selecting the chemical composition of the material, the microstructure can be optimized, improving the performance of the welded joints.

04 Summary

This paper summarizes the dynamic behavior of the laser welding molten pool, the evolution of microstructure, and the mechanism of pore formation. By deeply understanding these characteristics, the process parameters of laser welding can be optimized to improve the welding quality. Future research will continue to deepen the understanding of the molten pool characteristics, combining theories and methods from multiple disciplines to explore more efficient welding processes. The development of laser welding technology will bring more innovations and breakthroughs to modern manufacturing.

Vigor team have rich experience on laser welding and spare parts assembly by laser welding. If any question or any question we can help, please feel free to contact us at info@castings-forging.com