Knowledge

Analysis and Solution Measures for Gas Hole Defects in Ductile Iron Castings

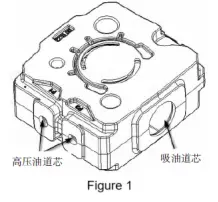

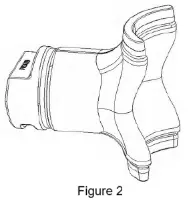

The rear cover is a key component in the construction of hydraulic motor systems and hydraulic pump systems for excavators, and the innovation and breakthrough in its casting process pose a major challenge. Without high-quality rear covers, the construction of high-quality hydraulic systems will face significant difficulties. The rear cover made of ductile iron has high requirements in terms of dimensional accuracy, inner cavity cleanliness, and material consistency. Therefore, when the company first produced this type of product, the difficulty of process research and development was relatively large. Recently, we produced a rear cover (as shown in Figure 1), with a weight of 77 kg, the maximum contour size of the casting is 342mm×303mm×137.5 mm, and the material is ductile iron. The wall thickness is relatively large, with the maximum wall thickness being 137.5 mm. The main structure includes two high-pressure oil channels and one oil suction channel. The core size of the oil suction channel is relatively large, with a diameter of 87 mm, a length of 130 mm, and a height of 137.5 mm, as shown in Figure 2.

-----------------------------

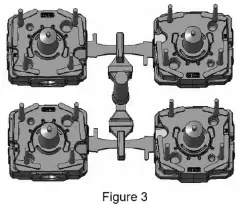

The initial designed gating system is shown in Figure 3: 4 pieces in 1 box, horizontal pouring, middle pouring, and the molten iron enters from the center position of the casting. F vertical:F horizontal:F inner = 1.4:1:2. This system is a semi-open and semi-closed gating system. In view of the dense needle-shaped gas holes defect that occurred in the production process of this blank, this study conducts an in-depth discussion on this issue and then proposes corresponding solutions.

--------------------------------

1. Defect Analysis

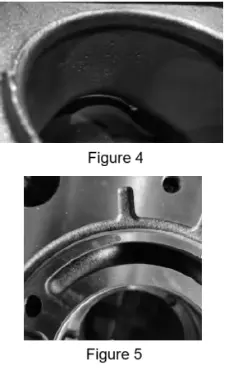

Porosity defects are one of the common defects in castings. The generation mechanism of porosity defects is complex and diverse, and there are many factors contributing to their formation, involving numerous processes in the casting production. The porosity defects found in the rear cover blanks of our factory can be classified into two types: one type of porosity defect is distributed below the oil suction channel, as shown in Figure 4. In the casting, the defect can be detected in the blank state; the other type is located 1 to 3 mm beneath the casting surface. In the blank state, the defect cannot be detected, but it will appear after processing, as shown in Figure 5.

----------------------------

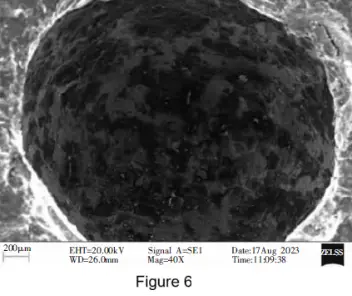

The defect location was analyzed by electron microscopy, as shown in Figure 6. The microstructure morphology indicates that the internal particles are evenly distributed and the surface is smooth. Based on this, it is judged to be a porosity defect.

-----------------------------

The initial judgment was mainly based on the relatively large thickness of the oil-absorbing channel core and the turbulent flow of molten iron formed below the oil-absorbing channel due to the middle injection gating system, which led to the formation of porosity. The gating system was adjusted by replacing the middle injection with bottom injection, but the problem still persisted.

According to literature research, the sources of gas mainly include magnesium vapor, hydrogen from ferrosilicon, and gases introduced into the molten iron due to interface reactions. During the solidification process, the oxide film on the surface of the ductile iron melt prevents the escape of gas pores, thereby causing the formation of gas pores.

Gas pores are a relatively common casting defect in cast iron parts, and the most common type of gas pores in ductile iron castings is subsurface gas pores, whose formation reasons are rather complex and mainly involve chemical reactions within the molten iron or between the molten iron and the sand cores and molds. Firstly, the first type of reactive gas pores refers to the honeycomb-shaped gas pores formed by chemical reactions between the chemical components within the molten iron or between the components and non-metallic inclusions, etc., which are in the shape of plows or balls and are relatively evenly distributed. Another type of gas pores is the reactive gas pores between the molten iron and the sand cores and molds. Generally, the thickness of the casting skin is within the range of 1 to 3 mm, and in some cases, it can only be exposed on the surface of a layer of oxide film. After machining or cleaning, the skin can reveal its original appearance. These gas pores are sometimes spherical or plow-shaped, with diameters typically ranging from 0.1 to 0.3 mm; sometimes they are elongated, with diameters reaching 7 to 10 mm; and most of them are perpendicular to the surface of the casting.

2. Causes of the Formation of Reactive Gas Porosity

The main components of the gas in reactive gas porosity include hydrogen (H2), carbon monoxide (CO), and carbon dioxide (CO2). The formation process of this phenomenon is quite complex, and the factors contributing to it include the following aspects.

2.1 Low Pouring Temperature of Molten Iron

If the pouring temperature is low, the molten iron is prone to solidification before the gases formed by the reaction are completely expelled. When the gases have already formed pores, the reaction is incomplete. Moreover, molten iron at high temperatures is close to a liquid state and has a relatively low viscosity, thus having an advantage in pressure transmission. Molten iron at low temperatures is essentially a semi-fluid with a high viscosity, and its ability to transmit pressure is weak. Even if the pressure is high, the actual pressure in the molten iron does not increase significantly. This phenomenon makes it difficult for gases to penetrate and be effectively discharged, thereby affecting the movement and diffusion of bubbles. During the actual pouring process, due to the low pouring temperature of the molten iron, the slag in the molten iron is not easily floated and removed. Therefore, there is more slag in the mold, and the FeO enriched in it reacts with carbon to generate CO gas.

2.2 High Moisture Content and Low Permeability of the Mold

If the mold has a high moisture content, the heat source during the pouring process has a significant impact on the generation of H2. Additionally, if the mold has low permeability during the casting process, these gases are difficult to escape, thus easily leading to the formation of reactive gas porosity.

2.3 High Gas Content in Molten Iron

If the gas concentration in the molten iron is high (including oxygen and hydrogen dissolved in the molten iron, which is one of the sources of H2, CO, and CO2 in reactive gas porosity), and these gases are difficult to be removed during the solidification process, it may lead to the formation of pores.

2.4 Severe Oxidation of Molten Iron

When the oxidation degree of the molten iron is high, oxides are generated, further dissolving oxygen. Moreover, oxides react with carbon to produce CO gas and other substances.

2.5 High Content of Elements S and Mn in Molten Iron

When the content of S and Mn in the molten iron is high, Mn combines with FeS to form MnS. Manganese silicate dissolves in the oxidation slag, lowering the melting point to a liquid state, which promotes the free FeO in the slag to fully contact with carbon and react, generating CO gas.

2.6 Influence of Product Structure

Based on data accumulation, ductile iron castings with wall thicknesses between 6 and 25 mm are prone to subcutaneous gas porosity. Therefore, in product design, the wall thickness should be designed to be less than 6 mm or greater than 25 mm.

3. Measures to Avoid Reactive Porosity

3.1 Increase Pouring Temperature

A higher pouring temperature prolongs the liquid state of the molten iron, facilitating the upward escape of gases and slag and reducing the likelihood of chemical reactions. Therefore, this method is the best way to eliminate reactive porosity. For instance, when pouring at 1300 to 1350 ℃, needle-like porosity in castings was observed, but when the temperature was raised above 1350 ℃, the porosity disappeared.

3.2 Enhance Permeability and Control Moisture Content in the Mold

For castings prone to reactive porosity, the moisture content in the core sand should be reduced to below 5%. Additionally, it is recommended to optimize the permeability of the mold to achieve a permeability rate of at least 80%.

3.3 Minimize the Gas Content in Molten Iron Before Pouring

For tools that come into contact with molten iron, such as ladles and slag skimmers, thorough preheating and baking are necessary. Before pouring, ensure that the slag is completely removed. The molten iron should be at a high temperature when it leaves the furnace and should be left to stand for a period of time to allow gases to escape.

3.4 Prevent Oxidation of Molten Iron

During melting and inoculation, the content of strong oxidizing elements in the furnace charge and various materials should be strictly controlled. Additionally, in the core and molding sand of the mold, supplementary materials such as coal powder or heavy oil can be added in appropriate amounts to enhance the reducing atmosphere within the mold and reduce or prevent the occurrence of reactive porosity. This is especially important for critical castings and those prone to subsurface porosity.

3.5 Selection of Spheroidizing Agents

Nickel-magnesium alloy spheroidizing agents are more effective in reducing defects compared to silicon-magnesium agents. Moreover, a higher pre-treatment temperature and shorter holding time of molten iron after treatment can also reduce subsurface porosity.

3.6 Design of Product Structure

When designing the product structure, the wall thickness should be kept either less than 6 mm or greater than 25 mm to reduce the probability of porosity.

4 Conclusion

After implementing the above strategies, our company has completely eliminated the problem of reactive porosity in ductile iron castings. Due to the high uncertainty in the process and origin of pore formation, if pore problems are found in actual production practice, a comprehensive study on the gas source, generation mechanism, physical form, etc. should be conducted to eliminate the occurrence of pore problems fundamentally.