Knowledge

A Comprehensive Guide to Residual Stress Elimination of Castings & Die-forgings: Principles, Techniques and Practical

1 Preface

During the processes of casting, welding, heat treatment, and machining of mechanical parts, residual stress - self-balanced internal stress that remains after the removal of external forces or temperature fields - is often generated. If residual stress is not effectively controlled, it can lead to quality issues such as deformation, cracking, and reduced fatigue life, directly affecting the reliability and service life of the product. Therefore, mastering systematic and feasible stress relief methods is an essential skill in mechanical design and manufacturing.

2. Main Sources of Residual Stress

|

Source |

Typical Process |

Generation Mechanism |

|

Thermal Stress |

Welding, heat treatment, casting |

Temperature gradients cause uneven local expansion/contraction of materials |

|

Mechanical Stress |

Machining, stamping, forming |

Non-uniform plastic deformation, residual deformation |

|

Transformation Stress |

Transformation heat treatment, quenching |

Volume changes during phase transformation generate internal tensile/compressive stress |

(The above classification is a conceptual explanation. The subsequent elimination methods are all based on these sources.)

3 Conventional Elimination Techniques

3.1 Heat Treatment Class

1. Stress Relief Annealing

Heat the workpiece to 0.5–0.7 Tm (50%–70% of the material's melting point), hold the temperature, and then cool it slowly to significantly reduce thermal stress.

2. Normalizing and Tempering

By controlling the cooling rate, the microstructure is homogenized, balancing strength and stress relief.

3. Low-temperature Aging (Natural Aging)

Place the workpiece at room temperature or low temperature for several days to several weeks to allow micro-stresses to relax on their own, suitable for high-precision small parts.

3.2 Mechanical/Non-thermal Class

1. Mechanical Stretching

1Apply axial tensile force to the welded part on a dedicated stretching machine to cause plastic deformation to counteract the original compressive stress, with an elimination rate of over 90%.

2. Vibratory Stress Relief (VSR)

Through resonance or harmonic vibration excitation, internal stresses are redistributed. Modern spectral harmonic vibration technology can select multiple frequencies for excitation at once, offering better results than traditional single-frequency vibration.

3. Shot Peening

Impact the surface with high-speed small balls to create a compressive stress layer, eliminating tensile stress on the surface and enhancing fatigue strength.

4. Deep Rolling/Ultrasonic Impact

Use rollers or ultrasonic waves to create a compressive stress layer on the surface of the workpiece, suitable for large and complex components.

5. Laser Peening/Laser Peening Strengthening

High-energy laser instantaneously melts/vaporizes the surface layer, generating a very short shock wave to form deep compressive stress, achieving both processing and stress elimination effects.

6. Ion Implantation

Inject an ion beam into the surface layer to alter the atomic structure and adjust the stress distribution.

3.3 Composite/Novel Techniques

1. High-energy Beam Processing

Electron beam, ion beam, or high-frequency high-energy beam can change the plasticity of metals at low temperatures to achieve rapid stress relief without significant heat-affected zones.

2. Pulse Current Treatment

Generate micro-thermal shock inside the steel through pulse current to promote stress relaxation, which has been verified effective in laboratories.

3. Pre-stretching + Annealing (Strain Annealing)

First, moderately pre-stretch the workpiece, then perform low-temperature annealing to achieve more thorough relaxation in the mutually offset stress field.

1. Preventive Measures in the Design and Manufacturing Stages

|

Stage |

Key Practices |

|

Structural Design |

Avoid sharp corners and uneven thickness; use rounded corners and gradually changing cross-sections to reduce stress concentration. |

|

Material Selection |

Choose alloys with low residual stress sensitivity or perform pre-heat treatment. |

|

Process Planning |

Arrange rough and finish machining sequences reasonably; relax the workpiece after rough machining before finish machining to prevent stress accumulation. |

|

Welding Process |

Control heat input and use layer-by-layer welding; perform mechanical stretching or vibration aging immediately after welding. |

|

Quality Inspection |

Use X-ray diffraction, blind hole method or ultrasonic testing to monitor residual stress in real time and adjust the process promptly. |

5 Case Overview

Mechanical Elimination of Residual Stress in Valve Body Welding

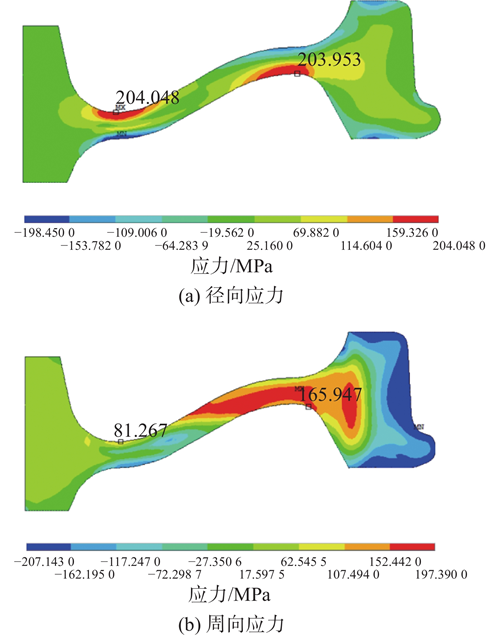

By applying radial pressure to the inner wall of the valve body (mechanical stress relief method), experiments and finite element simulations show that the reduction in residual stress is the highest.

Laser Shock Peening of Aircraft Engine Blades

After laser shock peening, a compressive stress layer about 0.5 mm thick forms on the blade surface, increasing the fatigue life by more than 30% without significant thermal deformation.

Spectral harmonic vibration aging for large-scale welded structures

By using multi-frequency harmonic excitation, residual stress can be reduced by 60% to 80%, and the working hours can be shortened by 50% compared with traditional annealing.

6 Selection Recommendations (Practical Tips)

|

Requirements |

Recommended Techniques |

Key Considerations |

|

Small batch, simple shape |

Mechanical stretching or natural aging |

Low equipment investment, good effect |

|

Large and complex structures |

Vibration aging (spectrum harmonic) or high-energy beam |

Strong adaptability, short working hours |

|

Surface strength improvement |

Blasting / deep rolling / laser shock |

Both compressive stress layer and hardening can be achieved simultaneously |

|

High dimensional accuracy requirements |

Low-temperature aging + ultrasonic impact |

Small thermal effect, controllable deformation |

|

New materials/additive manufacturing parts |

Pulse current + pre-stretching + annealing |

Balance microstructure and stress relaxation |

7 Conclusion

Residual stress is an inevitable by-product in mechanical manufacturing. However, through the combination of heat treatment, mechanical processing, vibration technology, and new high-energy/current methods, efficient and economical stress relief can be achieved at different stages and on different workpieces. The key lies in the prevention in the early design stage, process monitoring, and targeted selection of elimination processes to form a closed-loop control system, which can ensure the dimensional stability and reliable lifespan of the product.

Vigor has more than 20 years experience and the professional team in castings and forging as well as the post of treatment processes. If you have any question or products need to do, please feel free to contact us at info@castings-forging.com